Ideal for manufacturers who want to automate the initial stage of secondary packaging and prepare products for further processing or palletizing.

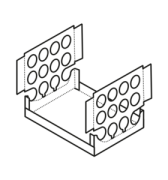

CFM-T is a forming machine designed for erecting trays from cardboard. Its robust and precise construction guarantees stable performance and a clean shape for each package. In a single-row design, it creates trays with the option of sealing with hot melt glue or a locking system.

Every movement is controlled with maximum precision – from feeding the blank to final forming. The machine is suitable for both stand-alone use and integration into fully automated lines, where it represents a reliable start to the secondary packaging process.

| Max speed | 25 cpm |

|---|---|

| Carton size (max) | 400 × 600 × 350 mm |

| Carton size (min) | 200 × 150 × 35 mm |